GE Aviation presented its new supersonic engine, intended for use in commercial aircraft, and mainly in the Aerion project.

At a press conference held with Aerion Corporation, GE Aviation announced that it has already completed the initial design of the first supersonic engine developed specifically for business jets.

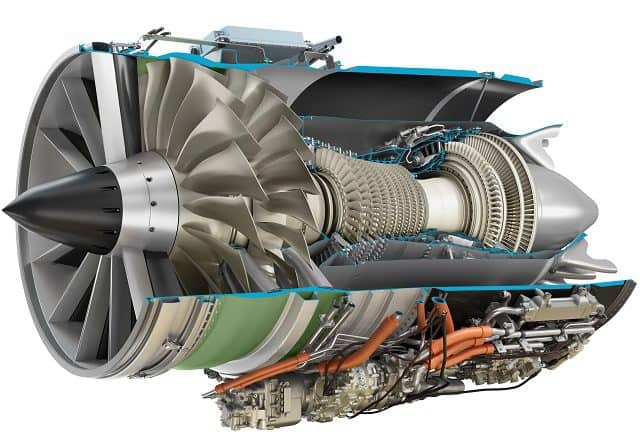

This new class of engines, unveiled today as GE's Affinity turbofan, is optimized with GE's proven technology for supersonic flight and will be developed in time for the launch of the Aerion AS2.

Affinity is a new class of mid-bypass ratio engines that deliver exceptional, balanced performance in both supersonic and subsonic flight. Affinity integrates a unique blend of proven military supersonic expertise, commercial reliability and the most advanced engine technologies for business jets.

GE's Affinity is a twin-shaft, twin-propeller turbofan managed by Full Authority Digital Engine Control (FADEC) electronic engine control for improved dispatch reliability and onboard diagnostics.

It is specifically designed to enable efficient supersonic flight over water and equally efficient subsonic flight over land without requiring modifications to current compliance standards. The engine is designed to meet stringent Stage 5 subsonic noise requirements and exceed current emission standards.

It is worth remembering that there is a rule in the US that limits supersonic flights on the continent.

GE Affinity features:

- Efficient performance throughout the flight envelope with a high altitude service ceiling of 60.000 feet.

- An advanced twin helix engine with the highest bypass ratio of any supersonic engine.

- A special, non-enhanced supersonic exhaust system.

- A proven engine core tailored from GE's commercial airline portfolio, which boasts billions of successful and reliable operational service hours.

- A tough combustor with advanced coatings to withstand long-term high-speed operation.

- Advanced acoustic technology designed to meet or exceed regulatory requirements.

- Additive design and GE manufacturing technologies to optimize weight and performance.

“Over the last 50 years, the speed of business aircraft has increased by less than 10%”, noted Brad Mottier, GE vice president and general manager, general and business aviation and integrated services. “Instead of flying faster, the cabins have grown in size and become more comfortable, and the range has become longer. With larger aircraft with more comfortable cabins and longer range available on the market, the next step is speed… made possible by GE's Affinity.”

After two years of preliminary study, GE Aviation and Aerion launched a formal process in May 2017 to define and evaluate a final engine configuration for the AS2 supersonic business jet. A GE project team, supported by a dedicated engineering team, continues to work with Aerion in a formal, staged process.

The next design review is scheduled for 2020 and will signal the start of detailed design and production of the test article.

Aerion is collaborating with GE Aviation, Lockheed Martin and Honeywell to develop the AS2.

“Our mission is to expand global mobility at supersonic speed, starting with business aviation and continuing with faster and bigger projects for business and commercial aviation alike”, revealed Tom Vice, CEO of Aerion. “GE Aviation is enabling this new era of efficient and sustainable supersonics with its pioneering work on the Affinity engine.”

Do you want to receive our news firsthand? Click Here and be part of our Group on Whatsapp or Telegram.